Orthotic Manufacture

Orthotic Manufacture For Healthcare Professionals

ACE has been manufacturing functional foot orthoses for over 20 years. We manufacture modular and bespoke insoles for the NHS, podiatrists, orthotists and other healthcare professionals all over the UK and Ireland.

Modular & Bespoke Orthotic Manufacture

If you are a healthcare practitioner looking to supply functional foot orthoses at your clinic then we can help. We have everything from experienced MSK podiatrists and less confident healthcare practitioners that use our services. Our team will not only make your insoles but will be able to offer advice and experience from our team of podiatrists if it is needed. We are not here to judge, we are here to help, so get in touch and we can discuss how to get you and your clinic set up as a trade partner today.

Our Range Of Functional Foot Orthoses

Our lab offers a variety of devices, feel free to get in touch and ask for some samples

Modular Insoles

With years of experience in both clinical and technical aspects of podiatry and manufacture we decided to create our own ranges of modular insoles.

Paediatric FiMs

A range of EVA high heel cupped functional devices for the child’s foot. These devices are available in neutral, 3 and 5 degrees.

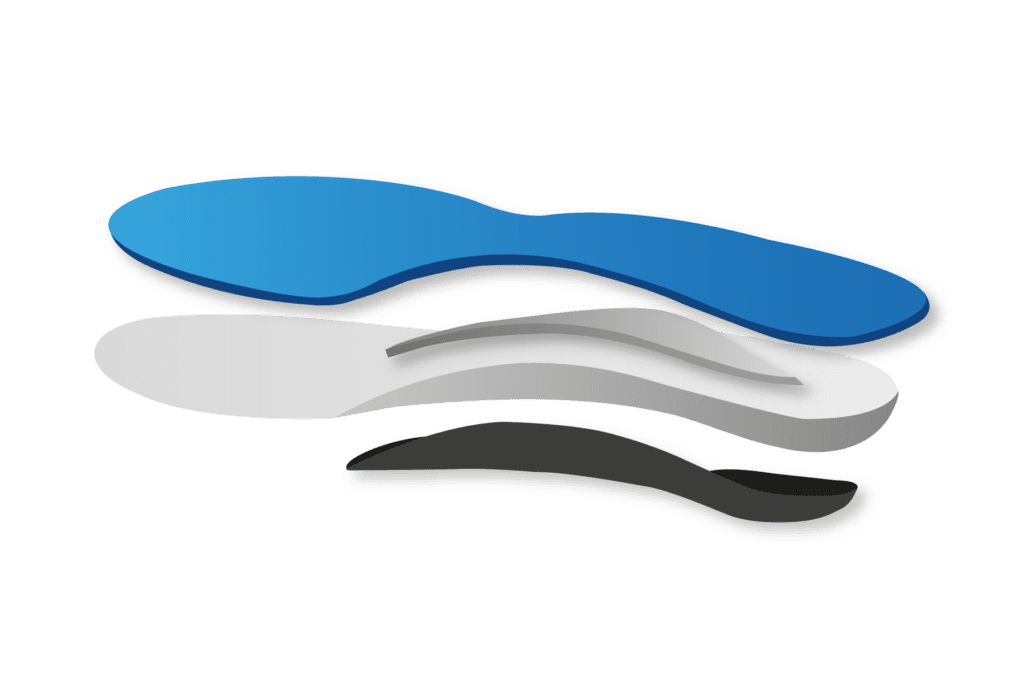

Adult FiMs

Our adult range of insoles that are available in low, medium and high density options. This is the perfect base to build your prescription from.

Bespoke Insoles

Bespoke insoles are made to your patients specific foot shape. In order to make these insoles you will need to capture the patients foot shape and send it to us. The most common ways to achieve this is to take a slipper cast, impression box or 3D scan. Once we receive the casts, impression box or scans at our manufacturing facility along with a filled out prescription we will then be able to make this product.

EVA CADCAMs

Computer Aided Design Computer Aided Manufacture EVA orthoses are a favourite amongst the NHS and many podiatrists. The EVA is available in A18, A30, A40, A50, A70, A30/50 & A50/70 densities (samples available on request). Patient compliance is very high with this device and the base is easily modifiable giving you plenty of prescriptive options.

Polypropylene (Plastic)

We vacuum form our plastic devices to your patients rectified cast. These devices are well tolerated and comfortable. Multiple finished and postings are available.

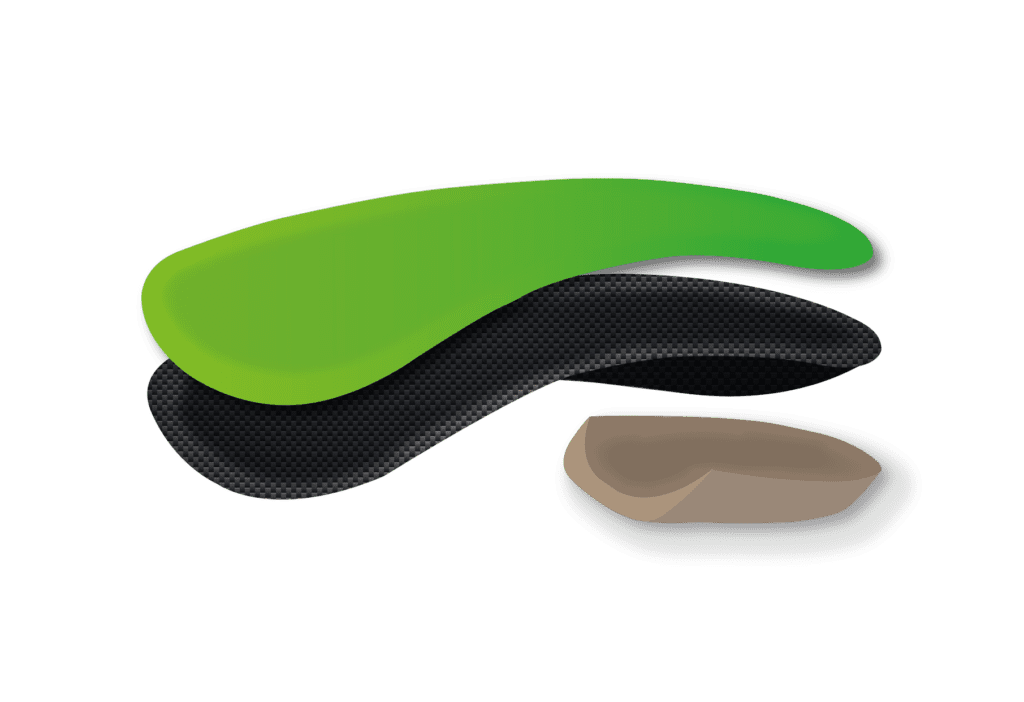

Carbon Composite

The most rigid and low profile of our devices. Perfect if more control is needed or if you are looking to fit the device in a lower profile shoe.

The Ordering Process

Get In TouchStep 1.

Set Up Account

For all new customers we advise getting in touch with our trade accounts team (trade@feetinmotion.co.uk) where they will be able to provide all of the relevant information including our latest price list, impression boxes and an invite to our manufacturing facility to meet the team (not compulsory).

Step 2.

Download Our Prescription Forms

Once the forms have been downloaded you will be able to create the relevant prescriptions for your patient’s needs.

Step 3.

Send Patient Cast/Impression/3D Scan (Bespoke)

Once we have received your patients foot casts, box or scan we can then start the manufacturing process.

Step 4.

Send Patient Prescription (Modular & Bespoke)

Whether you opt for modular or bespoke functional foot orthoses we will require a prescription form to be filled in and sent. This can now be emailed across or can be printed and posted and sent with the impressions or casts.

Step 5.

Manufacture

Once we have received the relevant information sit back and relax. Once the insoles have been manufactured we will post the devices to the desired location.

Customer Support

At ACE we don’t just manufacture insoles we offer our customers market-leading support. If you have any questions about your patient’s needs or feel as if you would benefit from a chat with one of our experienced podiatrists then that can be arranged. We are here to help you offer the best insoles to your patients.

Contact information

Official partners

Get in touch

Quality Certification – Why Is This Important?

As manufacturers of custom made orthotic medical devices we must have the relevant quality certification. This means going through regular audits to make sure our facility, materials and staff all fit standard requirements. We currently up to date and certified with ISO 13485:2016 which is seen as the international gold standard for quality in the medical device industry. As manufacturers of medical devices we are also registered with the MHRA.

As a healthcare practitioner who prescribers insoles it is up to YOU to check that your orthotic manufacturer has this certification and registration.